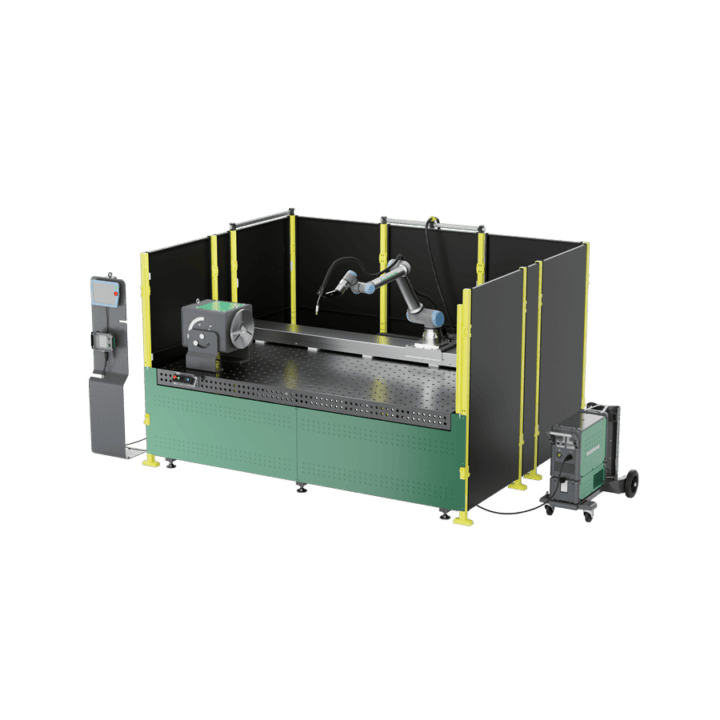

Migatronic System RM23

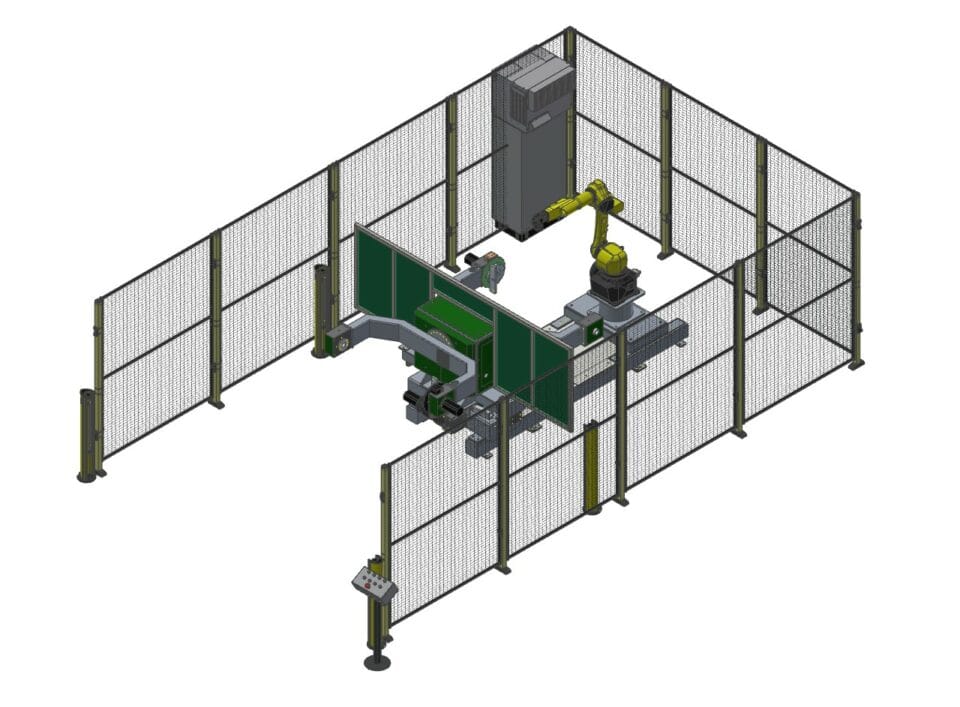

The pre-engineered welding system from Migatronic is designed to deliver optimal performance and increased capacity. The system includes separate working areas for both the robot and the operator.

Immediately usable

- Easy system installation

- Overhead crane access

- Easy to operate

Cost efficient

- Fast-track efficiency upgrade

- Low investment cost

- Future proof

Secure

- Meets safety regulations

- CE marking

- Proved and tested system

Increased production rate

- High output system

- Consistent quality

- IIoT ready

Product details

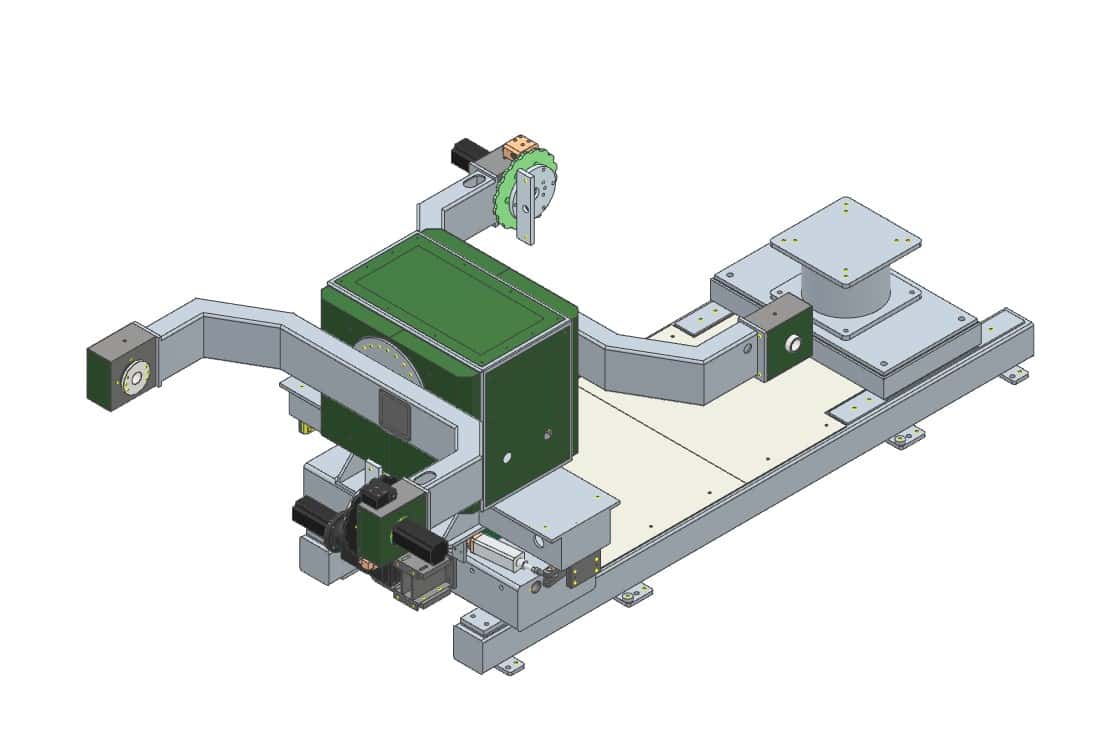

Manipulator range

5-axis indexing manipulator with two external axes. Can tilt and turn workpieces into any position, ensuring optimum welding position, even for complex workpieces.

Ø: 1000 mm

L: 1150 mm

250 KG

Your daily operation

An operator is necessary for the daily loading and unloading of components. The workpieces can be loaded using an overhead crane while the robot performs welding.

Included

- Fanuc Robot ArcMate 100iD/8L.

- Manipulator ready for fixtures.

- Fencing with light beam.

- Roll-liner for consistent wirefeed.

- Remote supervision and administration.

Available add-ons

- Fume hood with outlets for ventilation and exhaust.

- Retrofit adapter for old fixtures.

- Simulation Software from your preferred robotbrand.

- Visual and audible light indicators of machine status.

- Torch cleaning system.

- Light grid, laser scanner or roller door.

- Media transfer (signal, air, current) for manipulator.

Welding power sources

Welding packages for MIG, TIG and Plasma welding. Choose between

- Sigma Select

- Pi 350 DC

- Pi 350 Plasma With Synergic

- PowerArc Pulse

- Pulse

- IAC

- IGC

… and all welding function packages.

Wan't to learn more about Migatronic System RM23?

Service & Support

We offer various services to ensure that your equipment remains operational throughout its lifespan. These services include regular maintenance and training programs for your staff.

Additionally, we can provide support for fixture design and development, as well as robot programming, including online and offline programming. Our team of welding specialists can provide professional guidance and help develop welding procedures, while our trained technicians will keep your robot cell productive.

Learn more about our Support & Services.

Other standard Migatronic solutions

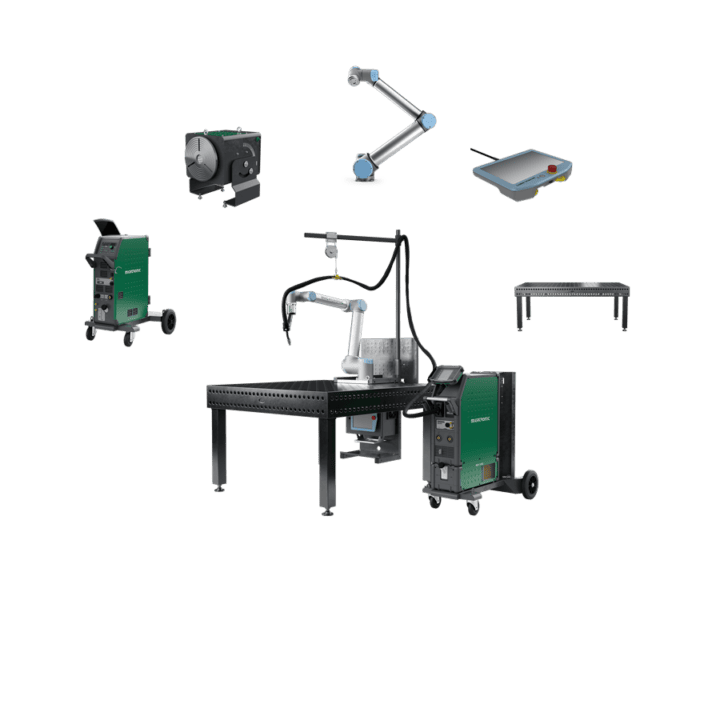

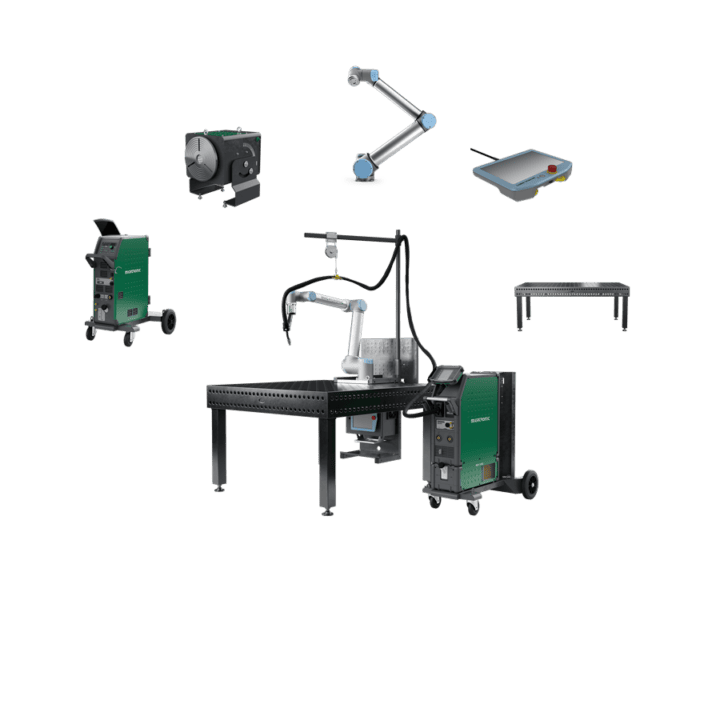

CoWelder track

CoWelder Basic