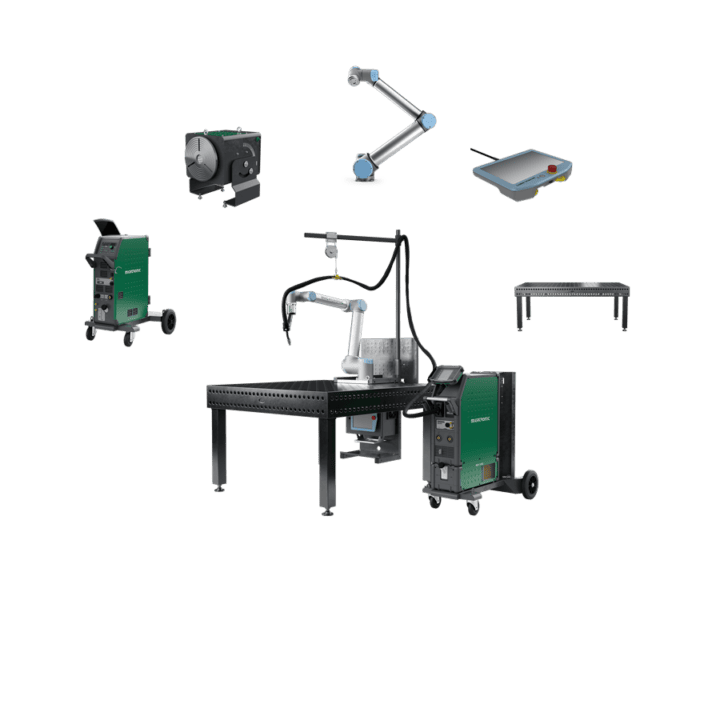

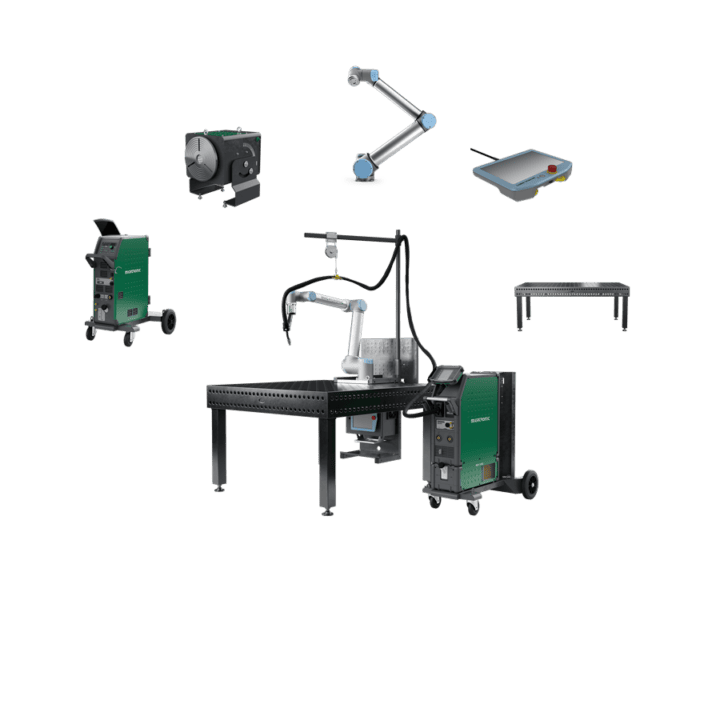

Migatronic Customised solution

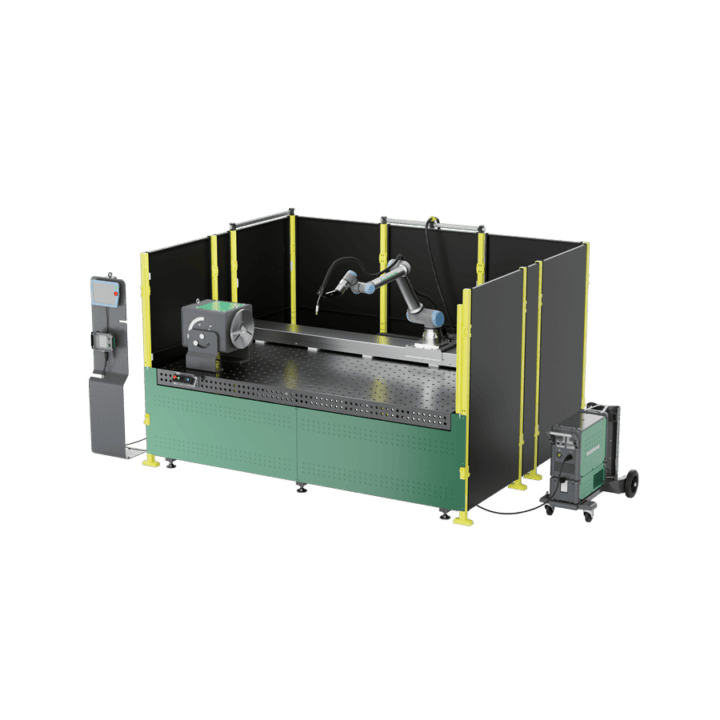

We would like to venture the claim that any welding and handling process can be automated, regardless of complexity. With a focus on your production needs, we develop in collaboration the best tailored automation solution that will be a benefit to your company.

Product details

Your needs are our starting point

Get it just as you want with a Costumised Solution

All factors are examined and evaluated when we are developing the optimal automation solution for your production. This includes all details such as weld quality, production volume requirements, and minimal error rates. All of this forms the basis for determining which solution will provide the greatest benefit to your company.

Get the robot you want

Your needs and requirements are the most important factors in the development of your automation solution. That’s why we choose the robot or robots that can best perform your welding and handling processes. We work closely with leading robot manufacturers from around the world, and are not married to anyone.

Access to welding specialists

When you collaborate with us, you gain access to over 35 years of experience in automating MIG, TIG, plasma, resistance, and laser welding. As a subsidiary of Migatronic A/S, a company that develops and manufactures welding machines, we have access to the latest knowledge in welding technology. Experienced welding specialists are involved in the development of your automation solution.

An ongoing partnership

Our project-based approach ensures a structured investment process in which you are involved in every phase. This includes ROI calculations, welding trials, a timeline, as well as the design and visualization of the solution. Our collaboration does not end when your automation solution is implemented. Together, we can continuously assess whether new technological approaches can optimize your solution.

Wan't to learn more about Migatronic Customised solution?

Service & Support

We offer various services to ensure that your equipment remains operational throughout its lifespan. These services include regular maintenance and training programs for your staff.

Additionally, we can provide support for fixture design and development, as well as robot programming, including online and offline programming. Our team of welding specialists can provide professional guidance and help develop welding procedures, while our trained technicians will keep your robot cell productive.

Learn more about our Support & Services.

Other standard Migatronic solutions

CoWelder track

CoWelder Basic

System RM21