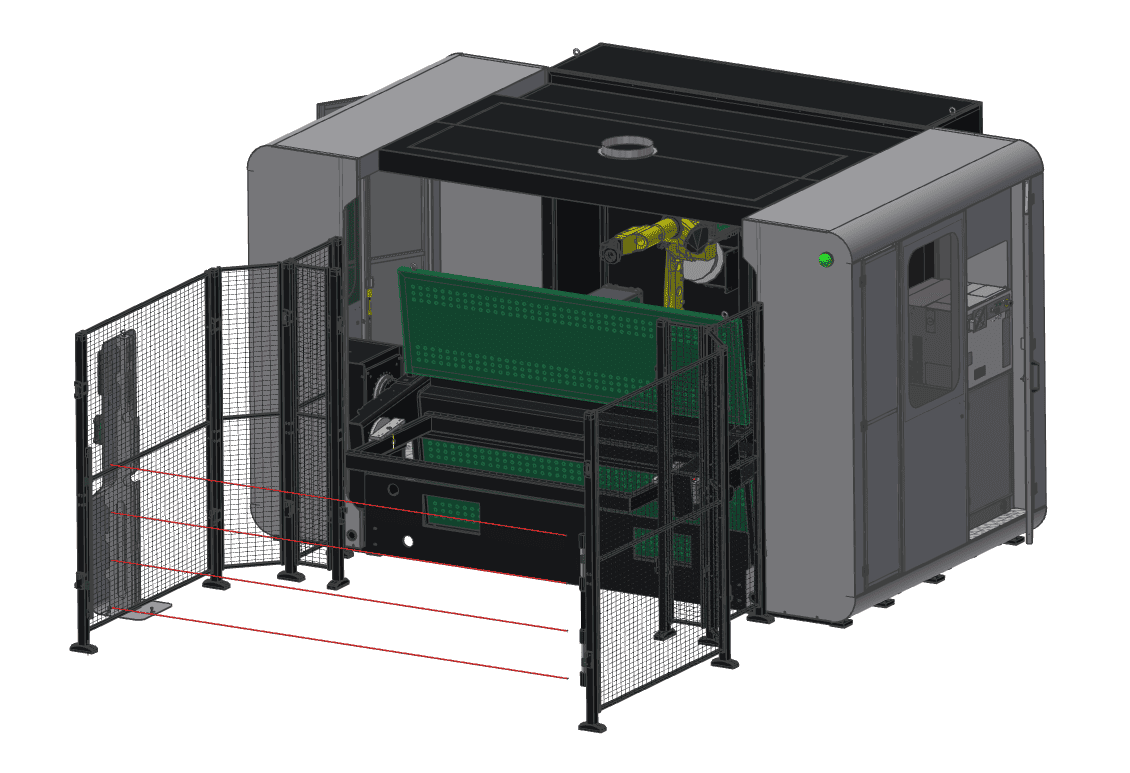

Customised CoWelder

Samson Agro optimized production of eco-friendly agricultural machines with Migatronic’s CoWelder robot. Flexibility, efficiency, and compliance ensured high demand was met…. Read more

From optimized standard solutions to flexible collaborative robots, we deliver comprehensive automation for every welding task.

We're not just vendors; we're your consulting engineers, ensuring you receive the correct solution. Automation is complex, and a poor choice could lead to significant financial losses. Our exceptional consultancy is key to your success.

We guide you expertly, adopting a systematic approach to craft a welding solution that fits your present and future needs. Think of us as part of your team, aiming to guarantee your project's success. Dive into automation with us, and we'll guide you to the right choice.

Reliable, efficient solutions that offer cost-effective alternatives to custom development.

The simplest collaborative automated welding solution on the market.

Customise your solution or assemble one from proven and extensively tested sub-units.

Be up and running within an impressive timeframe, starting from only two weeks. From conceptualization to implementation, our agile approach ensures swift and efficient deployment, saving you valuable time and accelerating your path to success.

Our prebuild industrial solutions are the masters of manipulating small and big workpieces. Tilt, index or rotate, we have a solution that can manipulate your workpiece into the optimum welding position.

Our prebuilt industrial solutions offer an accessible entry point into the world of automation, starting from an affordable price of just 105,000 euros. With our cost-effective solutions, you can embark on your automation journey confidently, knowing that efficiency and productivity are well within your reach.

CoWelder brings a new definition to the word flexibility in modern day industrial production. It is so easy to switch over the production that it pays off to automate welding of simple workpieces no matter the quantity or frequency. Be able to weld workpieces for specific orders at peak points or produce for stock at low volume times.

Using the robot arm's control pad, operators can effortlessly create welding programs with intuitive arm movements, bypassing the need for traditional programming via a teach pendant. Minimal training enables users to easily create new programs, adjust settings, and set welding paths with CoWelder, eliminating the need for programming expertise.

Designed to be the most cost-effective entry point into the world of automation, the CoWelder offers unparalleled value. As a collaborative robot solution, this cutting-edge technology starts at an incredibly competitive price point of 48,000 euros.

We offer a broad range of different CoWelders to variant needs. Go to our CoWelder univers on CoWerlder.com and explore the many opportunites.

All factors are examined and assessed when we develop the optimal customised solution for your production. We can custom-design your solution 100% or we can compile a solution of well-known and thoroughly tested sub-units like our CoWelder. With a focus on your production needs, we work together to develop the best automated solution that you need.

Take the first step in discovering if your production is ready for automation. Answer 10 questions and get clarity on the question: Is now the right time to start automating my welding?