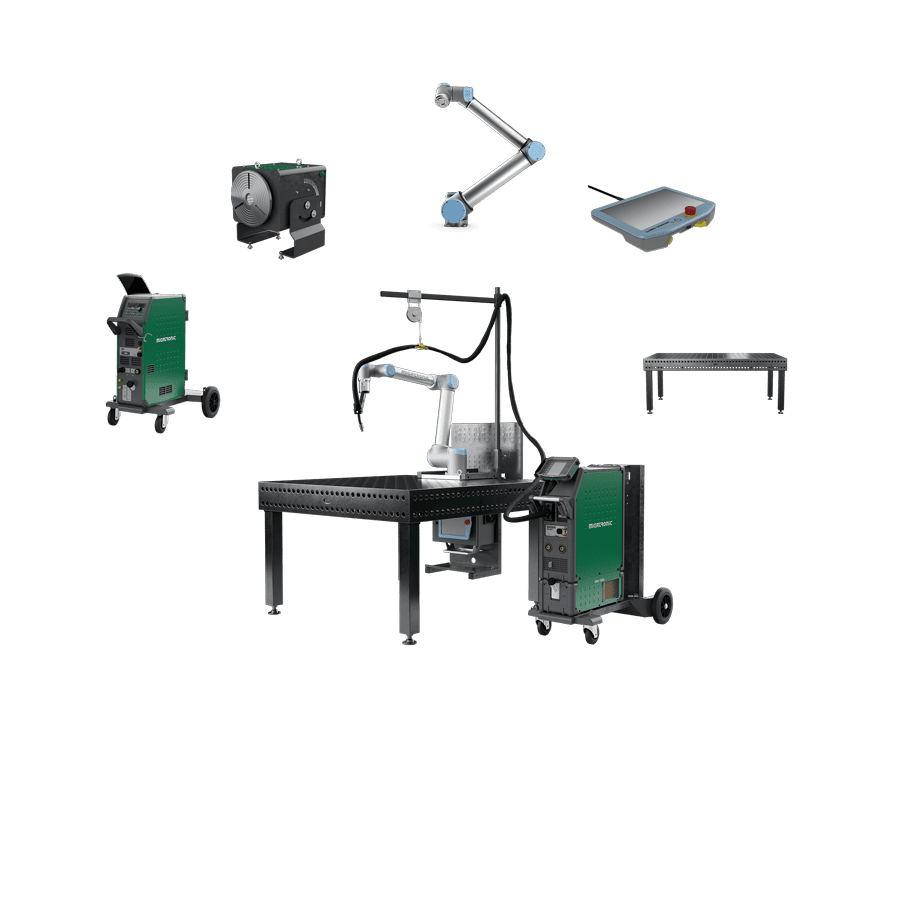

Migatronic Customised CoWelder

We understand that one size doesn't fit all. That's why we offer a fully customizable solution for our CoWelder product. If our CoWelder models don't perfectly match your requirements, we have the flexibility to craft a CoWelder that's tailored specifically for your production needs.

Same proven benefits

Relish the proven benefits of our CoWelder, but now enhanced and custom-fitted to align perfectly with your specific requirements.

Shape your success

Choose between a TIG or MIG welding machine, select the perfect size for your welding table, and enhance your setup with track and turn if necessary.

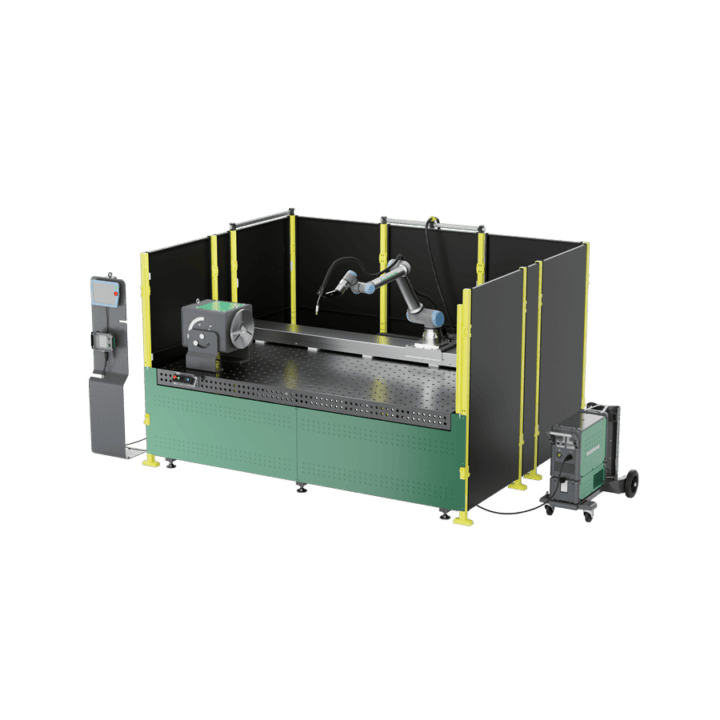

On the floor or on the wall

Customize your CoWelder for floor installation for traditional, stable setups, or opt for a wall-mounted configuration to save space and add an extra dimension to your welding capabilities

The sky is the limit

Let’s push the boundaries of what’s possible in welding technology and create a customised solution that truly reflect your needs and aspirations.

Product details

Collaborative welding

Fully customizable solution for our CoWelder product.

Migatronic CoWelder is a collaborative welding robot — a semi-automated solution that works together with the welder in a shared workspace. Automate your welding processes in a simple, fast and easy way compared to industrial robots. Integrate CoWelder in your production with minimum deployment time. Improve your productivity significantly without having any experience with automated welding.

Increase your arc time

Every minute your arc is off is unproductive. CoWelder will get the job done faster than any manual welder could ever do.

- CoWelder utilises 6 axes to move around the workpiece during welding. This agility and reach allows the robot to keep welding where a human arm with only 3 axes would need to stop to reposition.

- CoWelder can reach over double that of humans. It can keep welding for long stretches without reducing accuracy or having unnescessary start/stop.

- CoWelder will not make any stop and start in the middle of a weld. It will skip the detours and only make the most necessary torch movements. It will finish multiple workpieces without stopping.

- If your workpiece is small, place more workpieces in the reach of CoWelder and save valuable time. Combined with the Offset-function, arc time/hour will increase significantly.

Case

Improving Farming Efficiency with Customized Welding

Samson Agro optimized production of eco-friendly agricultural machines with a Customised CoWelder. Flexibility, efficiency, and compliance ensured high demand was met.

Because of a strongly growing market for environmentally correct solutions for distribution of organic fertilizer, the Danish company Samson Agro A/S sees a heavy demand for its slurry tankers, muck spreaders and other farm equipment. This requires maximum flexibility and performance in the company’s production, which is why it decided to invest in a new, custom-designed version of a collaborative welding robot, the Migatronic CoWelder.

Read the case: Samson Agro

How do we build a Customised CoWelder

You play an active role in every phase of the process, providing you with greater insight and ownership of your investment. We guide you through a proven step-by-step process to develop a CoWelder solution that aligns with your current and future needs. In other words, we become part of your team. Our role is to act as an advisor, facilitator, and supplier. Ultimately, our goal is to guarantee the success of your project.

Read more: How we work

Wan't to learn more about Migatronic Customised CoWelder?

Service & Support

We offer various services to ensure that your equipment remains operational throughout its lifespan. These services include regular maintenance and training programs for your staff.

Additionally, we can provide support for fixture design and development, as well as robot programming, including online and offline programming. Our team of welding specialists can provide professional guidance and help develop welding procedures, while our trained technicians will keep your robot cell productive.

Learn more about our Support & Services.

Other standard Migatronic solutions

CoWelder track

CoWelder Basic

System RM21