Ole Almeborg A/S, one of Denmark’s leading manufacturers of internal handling equipment, offers both standard and special solutions. This makes heavy demands on production flexibility, which is one of the main reasons why in recent years the company has invested in collaborative welding robots and cutting-edge automated welding solutions.

Collaborative robots and large robot cells

Since 1967, Ole Almeborg A/S has designed and produced internal handling equipment, including highlifters and pallet trucks.

Ole Almeborg’s wide product range is split into two production units: one for components for internal handling solutions and one for batch production of components for pallet trucks. With the aim of modernising and optimising both production units, the company has in recent years invested in several robot solutions from Migatronic and Migatronic Automation.

“Since 2015, we have invested in a number of welding solutions from Migatronic Automation, ranging from collaborative robots to large robot cells. The solutions are better than could be expected; they have made our production units more flexible and significantly increased our capacity, without compromising efficiency and welding quality“, Morten Jørgensen, Production Manager says.

Inspirational co-operation

In 2017, Ole Almeborg invested in a Migatronic CoWelder welding robot for the production of stainless components. According to Morten Jørgensen, the robot has optimised the welding processes of this production line so much so that the company has invested in yet another CoWelder:

“Our employees used to manually weld the small components, which is difficult and time-consuming. The CoWelder is perfect for this job. So we have invested in another CoWelder, and we already contemplate buying additional two“, says Morten Jørgensen.

Increases capacity by 25 per cent

Ole Almeborg’s other production unit manufactures components such as tension rods for pallet trucks, highlifters and stackers in large batches. One customer, viz. Toyota Material Handling, stands for more than half of the company’s turnover.

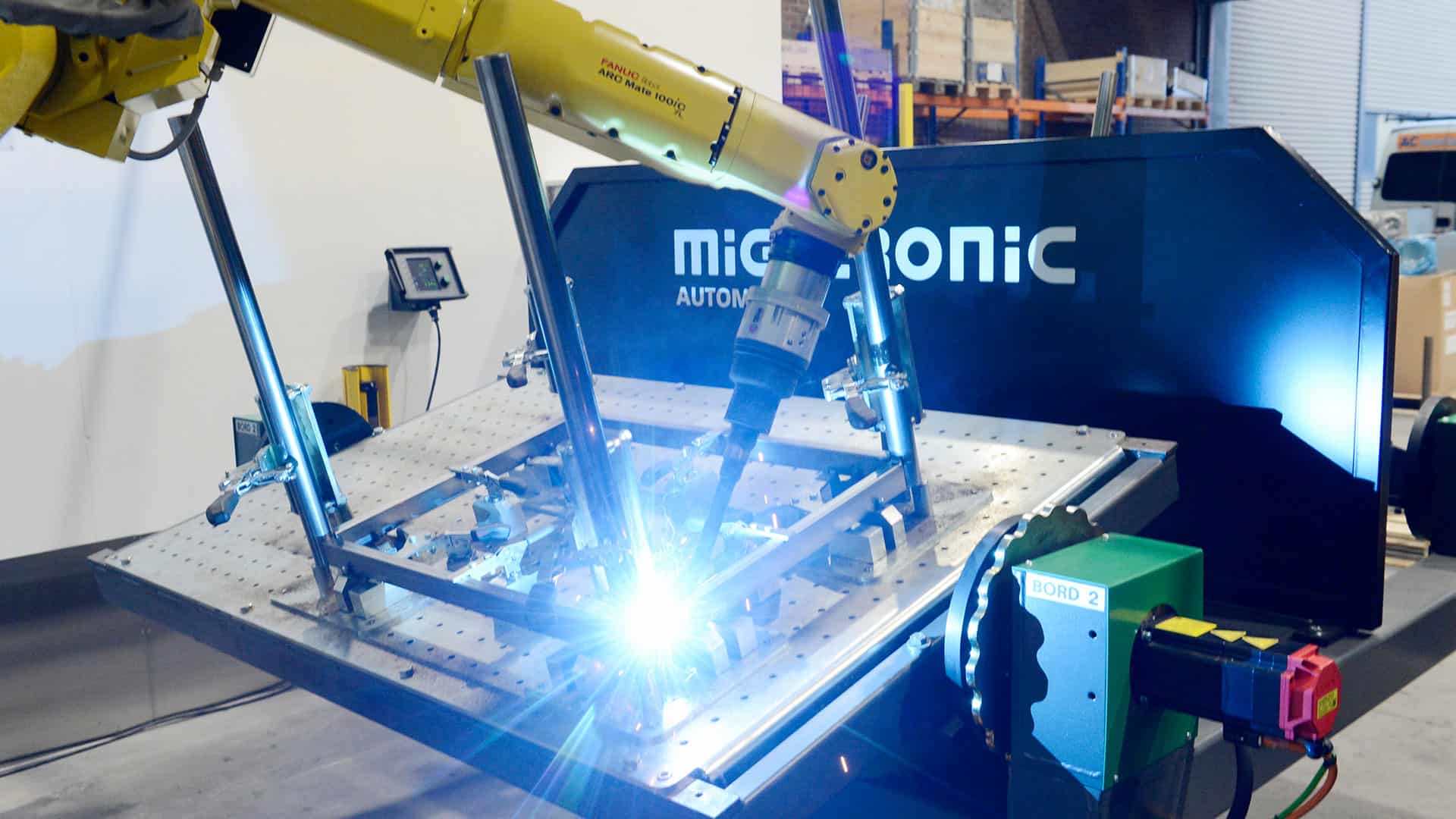

The batch production unit used to be operating to full capacity with components for Toyota and other external customers. However, since delivery of the two new robot cells, one of which is a so-called twin cell with two welding robots and a manipulator, the company has improved its production capacity by around 25 per cent. Consequently, it is now possible to produce a far greater number of components – also for the company’s own products.

Twin robot cell

“Migatronic Automation has helped us to rationalise our welding production. The twin cell is dedicated to our biggest batch productions and welds high-quality products at a rapid rate. This has significantly improved our annual production capacity for tension rods from 80,000 to just over 100,000. On the other hand, the single cell is equipped with five different fixtures, providing flexible handling of small batch production of special components“, says Morten Jørgensen, production manager in Ole Almeborg.